Automatic doy bag packing solution for 25-500gram nuts

Machine introduction:

This unit machine including one set ZL20-1.6L multi heads weighing machine for weighing two different product, one set ZL8-230 rotary bag taking opening filling sealing machine, one set DT5 bucket elevator and one set safety platform and ladder. The main machine are control by siemens PLC and operate by touch screen .Adopt famous Electrical accessories. High automation and easy to operate. Widely use by the different industry like Daily chemical, food, chemical, and etc.

Machine details:

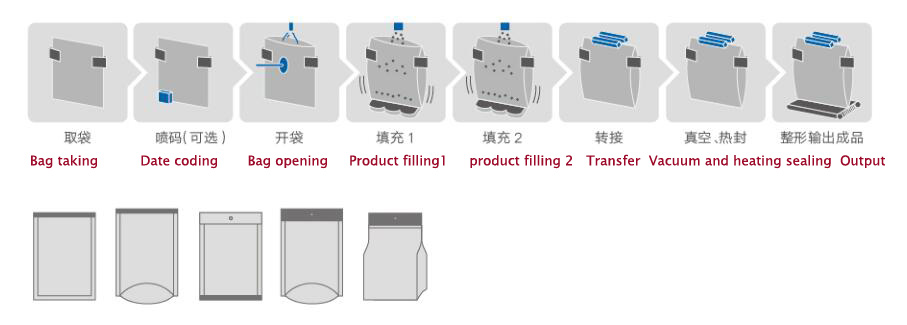

1, Model of ZL8-230 Rotary packing machine(doy packer with zipper)

Function and characteristics

1 、 Facile da usare , adotta un PLC avanzato di Siemens, accoppiato con touch screen e sistema di controllo elettrico, l'interfaccia uomo-macchina è amichevole.

2、La conversione di frequenza regola la velocità: questa macchina utilizza apparecchiature di conversione di frequenza, può essere regolata all'interno dell'intervallo in base alle esigenze della realtà in produzione

3 、 Controllo automatico: nessun errore di busta o busta aperta, nessun riempimento, nessun sigillo. la borsa può essere riutilizzata, evitando di sprecare materiali di imballaggio e materie prime.

4、Dispositivo di sicurezza: arresto della macchina a pressione dell'aria anormale, allarme di disconnessione del riscaldatore。

5 、 La larghezza delle borse può essere regolata dal motore elettrico. Premere il pulsante di controllo per regolare la larghezza delle clip, operare facilmente e risparmiare tempo.

6, può essere abbinato alla porta di sicurezza in vetro. Allo stesso tempo, potrebbe prevenire la polvere.

7, utilizzare il cuscinetto in plastica, non è necessario mettere olio, meno inquinamento.

8, non utilizzare pompa per vuoto dell'olio, evitare di inquinare l'ambiente nella produzione.

9、The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

10、Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

11、With different feeders changed to pack solid, liquid, thick liquid, powder and so on

12、The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on

Preformed bag made by film and paper.

specificazioni

| Modello | ZL8-230 |

| Posizione di lavoro | posizione di lavoro otto |

| Materiale sacchetto | Laminated film |

| Modello di sacchetto | Doy packer with zipper ,pillow bag |

| Dimensione della borsa | W:100-230mm L:150-350mm |

| Velocità | 10-35pouches/min(The speed depends on the product status and filling weight)) |

| Peso | 1400 KG |

| Voltaggio | 380 V 3 fasi 50 HZ / 60 Hz |

ZL20-2.5L multiheads combination weighing machine

Ambito di applicazione:

It is suitable for high-speed weighing of a single material, formula mixing of multiple materials: the longest material is 60mm, and the single material is less than 60g, such as instant oatmeal and mixed nuts.

Caratteristiche:

The High-speed mode can be used for a single material;

The Weight Of the mixture can be compensated by the operation of the last material;

Using High-precision,high-standard special sensors;

Intelligent Fault Alarm prompt, maintenance is more convenient;

High-speed synchronous discharge function, effectively prevent material blockage;

The Highly integrated modular design adopts CAN bus technology;

Modbus industry standard communication protocol, realizes the combination of the combination scale and the packaging machine interface;

Other functions and features of the same generation model;

For Viscous Materials, anti-stick measures such as 60° chassis and Teflon coating can be used.

Mechanical Characteristics And product characteristics:

Separate Upper Hoppers are used for a variety of mixed formula materials;

Adopt independent main vibration machine to control the feeding thickness of different materials respectively;

The Integral Chassis and middle seat enhance the rigidity and strength of the machine, making the weighing more accurate;

The Chassis And chute adopt compatible design. When weighing a single material, it can be replaced with a double-port unloading tray, which can be equipped with a double-packing machine;

The Unified Design standard and the mold making process make the interchangeability of each part stronger.

Thestable Aluminum shell structure makes the hopper run more stably and the readings are more accurate. The integral chassis and the middle seat enhance the strength of the machine, making the hopper's stabilization time shorter;

specifiche tecniche:

| Modello | ZLJ20-2.5L |

| Code | A20-2-2 |

| Target weight | 10-1000gram |

| Precisione | X(0.5) |

| Maximum speed | 65B/M (Mixed product) /100B/M Single product |

| Volume | 2.5L |

| Touch screen | 10.4' |

| Optional | Dimple Plate/Timing Hopper/Printer/Reject Device |

| Modalità di guida | Step motor |

| Energia | 220V/2000W/50/60HZ 16A |

| Packing dimension | 1920*1650*1620 |

| Peso della macchina | 850kg |